- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

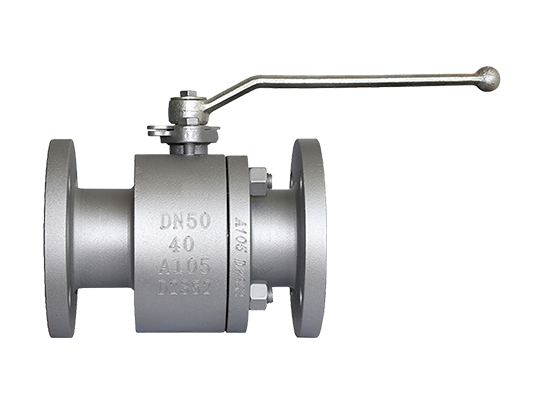

What are the Advantages of Floating Ball Valve Compared with Other Valves?

2025-06-09

The key to floating ball valve is that its ball has no fixed shaft support running through it. When the valve is closed and needs to be sealed, it is the pressure generated by the liquid or gas flowing in the pipeline that pushes the ball tightly against the sealing surface. When the valve is opened and closed, only one side of the rod is responsible for driving the ball to rotate. Compared with other valves, the primary advantage of this design is reflected in the principle of how it achieves sealing.

The ball produces axial displacement under the action of the medium pressure, dynamically pressing the downstream valve seat to form a positive seal. This mechanism enables the floating ball valve to maintain reliable sealing under low pressure conditions, while traditional gate valves often have insufficient sealing force under low pressure. The opening and closing operation only requires a quarter of the valve stem rotation stroke, which is significantly faster than the stop valve that requires multiple turns of rotation or the gate valve that requires vertical lifting space.

The compact design is due to the elimination of the upper bearing support structure. There is no complex chamber structure inside the valve body, forming a full-diameter flow channel to avoid turbulence. Compared with the reduced-diameter valve, the floating ball valve has a flow resistance coefficient close to the level of the straight pipe section, which can reduce system energy loss. Maintenance convenience is reflected in the fact that the valve seat assembly can be replaced online without disassembling the entire valve body. This feature is of key value in the continuous operation scenario of the pipeline system.

In terms of material utilization, the suspended ball reduces the requirements for precision machining and the amount of large alloy forgings. The double-blocking discharge function is achieved through two independent valve seats, allowing the valve cavity pressure to be safely released.