- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

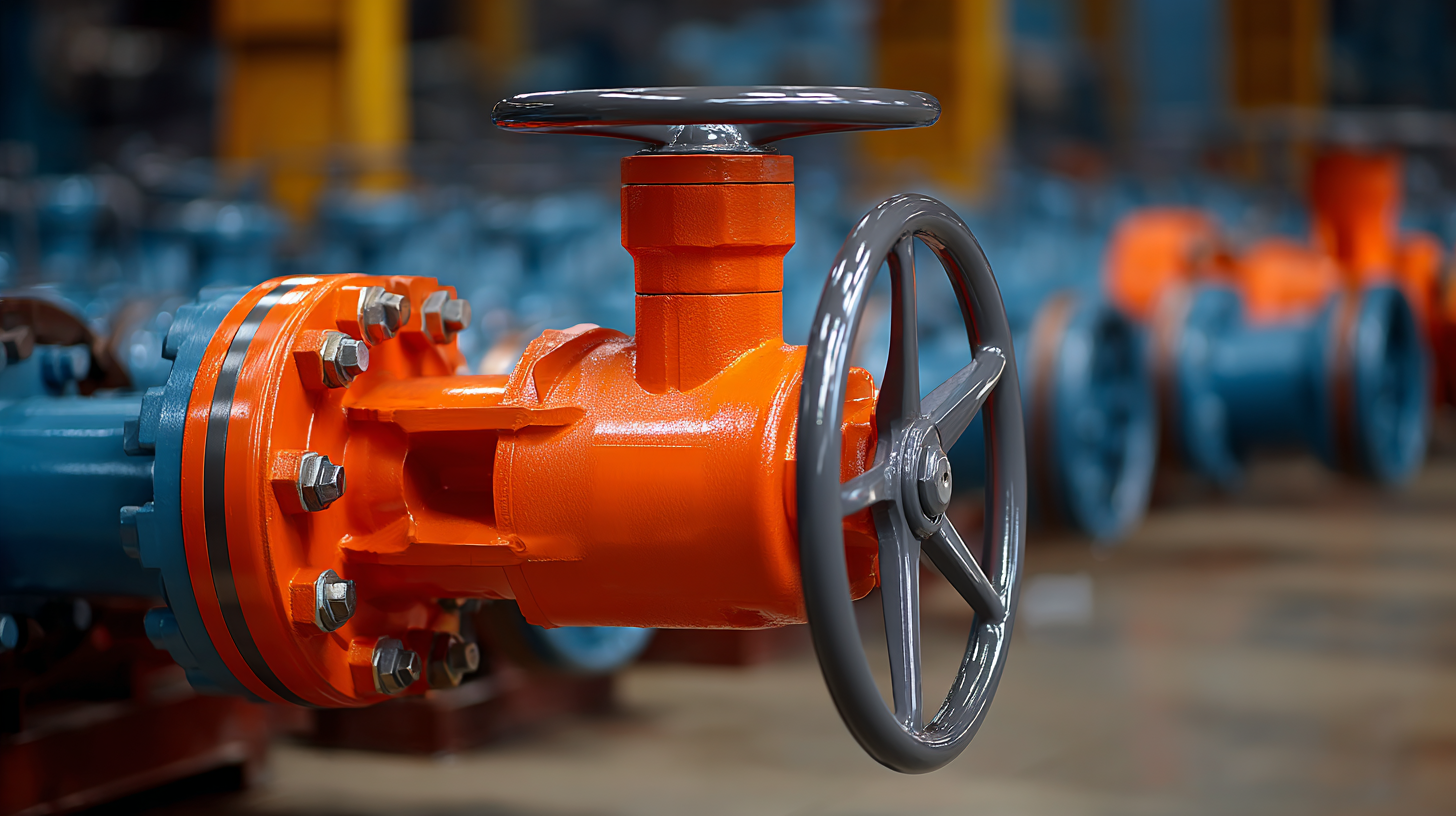

How to Choose the Best Concentric Butterfly Valve for Your Industrial Needs

In the ever-evolving landscape of industrial fluid control, the selection of the appropriate valve plays a crucial role in ensuring efficiency and reliability. Among various options, the Concentric Butterfly Valve has garnered significant attention due to its unique design and operational advantages, particularly in applications requiring tight shutoff and low-pressure drop. According to a recent market research report by MarketsandMarkets, the global butterfly valve market is projected to reach USD 6.69 billion by 2026, driven by the rising demand for efficient fluid management systems across various sectors. As industries continue to expand, understanding the specific needs—such as size, material, and application environment—will be integral to choosing the best Concentric Butterfly Valve suited for your requirements, ensuring optimal performance and cost-effectiveness in your operations.

Understanding Concentric Butterfly Valves: Key Features and Benefits

Concentric butterfly valves are essential components in various industrial applications, renowned for their simplicity and efficiency. One of the primary features of these valves is their unique design, which allows the disc to rotate around a central axis, providing a tight seal when closed. This design not only reduces the likelihood of leakage but also minimizes resistance to the flow of fluids, making them ideal for both on-off and throttling applications in water treatment, chemical processing, and HVAC systems.

Concentric butterfly valves are essential components in various industrial applications, renowned for their simplicity and efficiency. One of the primary features of these valves is their unique design, which allows the disc to rotate around a central axis, providing a tight seal when closed. This design not only reduces the likelihood of leakage but also minimizes resistance to the flow of fluids, making them ideal for both on-off and throttling applications in water treatment, chemical processing, and HVAC systems.

In addition to their advantageous design, concentric butterfly valves offer significant benefits, including ease of maintenance and lightweight construction. Their compact size makes installation in confined spaces simpler compared to other valve types. Moreover, these valves can handle a range of temperatures and pressures, catering to diverse industrial requirements. With options for various materials, including stainless steel and plastic, businesses can select valves that are best suited for their specific operational environments, ensuring lasting performance and reliability.

Comparison of Materials: Selecting the Right Valve Material for Durability

When selecting a concentric butterfly valve for industrial applications, the choice of materials is critical for ensuring durability and performance. The primary materials used for butterfly valves include stainless steel, cast iron, and plastic.

Stainless steel is favored for its excellent corrosion resistance, making it ideal for applications in harsh environments, such as chemical processing. It can withstand high pressures and temperatures, thus offering a longer service life compared to other materials.

Cast iron, on the other hand, provides a cost-effective solution for lower pressure applications. Its sturdiness is beneficial in handling substantial weight and high flow rates, but it may be prone to rust when exposed to moisture unless properly coated. Plastic materials, like PVC or PVDF, are advantageous when handling corrosive fluids; they maintain excellent chemical resistance but may have limitations in terms of pressure and temperature tolerance. Therefore, understanding the specific demands of your application—whether it requires corrosion resistance, pressure handling, or cost-effectiveness—is essential in selecting the right valve material for optimal performance in your industrial needs.

Sizing Matters: How Proper Sizing Affects Performance and Efficiency

When selecting a concentric butterfly valve for industrial applications, proper sizing is critical to ensuring optimal performance and efficiency. A valve that is too large may lead to turbulence and increased pressure drops, ultimately reducing flow control and leading to additional energy costs. Conversely, a valve that is undersized can result in insufficient flow rates, causing operational delays and impacting overall system performance. Understanding the flow requirements and system characteristics is essential when determining the appropriate valve size.

Moreover, it's essential to consider the specific operating conditions, such as temperature, pressure, and the nature of the fluid being controlled. Each of these factors can significantly influence the sizing and consequently the valve's efficiency. Valves should be selected not only based on nominal pipe size but also on the actual flow conditions to ensure that they perform effectively throughout their service life.

By taking the time to accurately assess these parameters, industries can avoid common pitfalls and enhance the longevity and reliability of their valve systems.

Performance Metrics: Evaluating Flow Coefficient (Cv) for Optimal Operation

When selecting a concentric butterfly valve for industrial applications, understanding the flow coefficient (Cv) is critical for ensuring optimal operation. The flow coefficient is a key performance metric that quantifies the valve's ability to allow flow. It defines the volume of water at a specific temperature that can flow through the valve per minute under a given pressure drop. Higher Cv values indicate a greater flow capacity, making it essential to match the valve's Cv with the system's operational requirements.

Evaluating the Cv helps industrial engineers determine the most suitable valve for their specific applications. Factors such as the fluid type, temperature, pressure drop, and required flow rate must be considered to achieve the desired performance. An improperly sized valve can lead to inefficient flow control, increased wear, and higher energy costs. Thus, a thorough assessment of the Cv in relation to these performance metrics ensures that the selected concentric butterfly valve meets the operational demands efficiently and effectively.

Cost-Effectiveness: Analyzing Long-Term Savings vs. Initial Investment

When selecting the best concentric butterfly valve for industrial needs, cost-effectiveness plays a vital role. Analyzing long-term savings versus the initial investment can lead to better decision-making. For instance, while a higher quality valve may incur greater upfront costs, its durability and reduced maintenance needs can lead to significant savings over time. Industry projections indicate that investing in advanced technologies can yield returns through enhanced operational efficiency, with the valve market expected to grow steadily alongside industrial applications.

**Tip:** Consider the long-term operational costs when purchasing valves. Evaluate maintenance requirements and lifespan, which can significantly affect total ownership costs.

Moreover, specific market reports suggest that the concentric butterfly valve sector is poised for growth, driven by increasing industrial applications and the demand for energy-efficient solutions. Understanding the market dynamics, such as the anticipated compound annual growth rate of various sectors, can further inform your choice.

**Tip:** Research the latest industry analysis to identify innovative valve technologies that align with your operational goals, as they can contribute to both cost savings and efficiency upgrades.