- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China's Quality Upgrade in Best Reduced Bore Ball Valves Driving Global Sales Growth

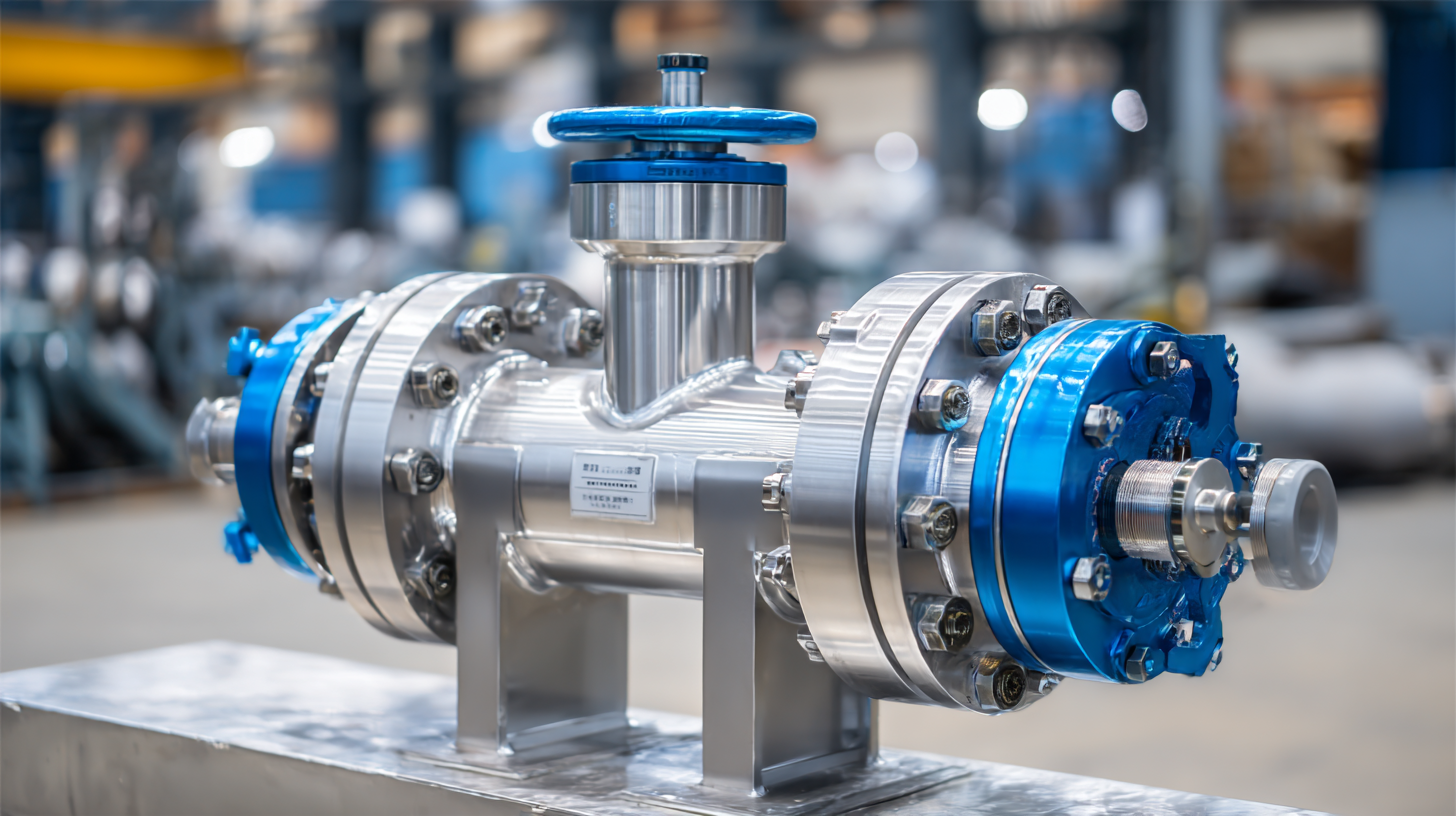

In recent years, China's manufacturing sector has witnessed a significant transformation, particularly in the realm of Reduced Bore Ball Valves, which has positioned the country as a leading exporter in the global market. According to industry reports, the global ball valve market is projected to reach approximately $10 billion by 2027, with a notable surge in demand driven by advancements in industrial applications and the energy sector. China's ability to produce high-quality Reduced Bore Ball Valves has been pivotal, contributing to remarkable sales growth and enhancing its reputation as a supplier of choice for international buyers. Furthermore, with stringent quality standards and innovative manufacturing technologies, Chinese factories are not only meeting but exceeding global benchmarks, further solidifying their top ranking in the export market. As companies worldwide seek reliable and efficient valve solutions, the emphasis on quality and performance in Reduced Bore Ball Valves continues to drive substantial growth and competitiveness in this vital industry.

China's Innovations in Reduced Bore Ball Valve Manufacturing

China has made significant strides in the manufacturing of reduced bore ball valves, showcasing a profound commitment to innovation and quality enhancement. The country's manufacturers have embraced advanced technologies and sophisticated production techniques that not only improve the durability and efficiency of these valves but also meet international standards. By integrating smart design and high-grade materials, Chinese manufacturers are able to offer products that are both reliable and cost-effective, making them highly competitive in the global market.

Furthermore, the push for quality upgrades is evident in the research and development initiatives that major players in the industry have undertaken. Collaborations with academic institutions and investment in cutting-edge machinery have paved the way for breakthroughs in valve performance. This focus on innovation is not just about keeping pace with global trends; it reflects a proactive approach to addressing the specific needs of diverse markets. As a result, China's reduced bore ball valves are increasingly recognized for their superior performance, further stimulating growth in international sales and solidifying the country's position as a leader in the valve manufacturing industry.

China's Quality Upgrade in Best Reduced Bore Ball Valves Driving Global Sales Growth

Key Features of High-Quality Reduced Bore Ball Valves

The evolution of reduced bore ball valves has marked a significant milestone in the modern manufacturing landscape, particularly in China. The key features that define high-quality reduced bore ball valves include superior materials, precision engineering, and enhanced sealing technologies. Manufacturers are increasingly adopting advanced alloys and composites that guarantee durability and resistance to corrosion, ensuring these valves perform optimally even in the most demanding environments.

Moreover, the precision engineering involved in the production of these valves allows for tighter tolerances and improved flow characteristics. This results in reduced pressure drops and energy efficiency, making them an attractive choice for industries looking to optimize their operations. Enhanced sealing technologies, such as advanced O-ring designs and multi-layer seals, further improve reliability and longevity, reducing the risk of leaks and the need for frequent replacements. As these features gain recognition, global sales of high-quality reduced bore ball valves are on the rise, driven by industries seeking efficiency and sustainability in their processes.

China's Quality Upgrade in Best Reduced Bore Ball Valves Driving Global Sales Growth - Key Features of High-Quality Reduced Bore Ball Valves

| Feature | Description | Market Impact | Growth Rate (%) |

|---|---|---|---|

| Material Quality | High-grade materials for durability and corrosion resistance | Enhances market trust and product longevity | 15% |

| Precision Engineering | High-precision manufacturing techniques for enhanced performance | Drives efficiency and reliability | 12% |

| Environmental Standards | Compliance with international ecological regulations | Improves export capabilities and market reach | 20% |

| Innovation | Incorporation of advanced technologies in design | Increases competitiveness in global markets | 18% |

| Customization | Tailored solutions to meet specific client needs | Boosts customer satisfaction and loyalty | 22% |

Market Trends Driving Global Demand for Reduced Bore Ball Valves

The market for reduced bore ball valves is experiencing significant growth, driven by various trends that highlight their efficiency and reliability in fluid control applications. The increasing demand for high-performance valves in industries such as oil and gas, chemical processing, and water treatment is pushing manufacturers to focus on quality upgrades in their offerings. In China, technological advancements have led to improved designs that not only enhance performance but also ensure compliance with international standards, making them more appealing in the global market.

As demand surges, companies are encouraged to assess their supply chains and production processes. Tips for manufacturers include investing in advanced automation technologies to streamline production and minimize defects. Additionally, collaborating with industry leaders can provide valuable insights into customer needs and preferences, allowing for tailored solutions that meet market demands more effectively.

Moreover, understanding the key factors driving market trends, such as sustainability and operational efficiency, can help companies refine their product lines. Emphasizing the long-term cost benefits of reduced bore ball valves can appeal to budget-conscious consumers while promoting environmental responsibility through energy savings and reduction of waste. By aligning product development with these trends, manufacturers can capitalize on the growing interest in reduced bore ball valves worldwide.

Case Studies of Successful Adoption in International Markets

In recent years, China's manufacturing sector has witnessed a significant quality upgrade in reduced bore ball valves, positioning itself to capture a larger share of the global market. This transformation is not merely about meeting domestic demands; it involves sophisticated engineering and adherence to international standards. Case studies from international markets reveal that companies adopting these advanced ball valves have experienced remarkable improvements in efficiency and reliability. For example, a European energy plant report indicated a 25% increase in operational efficiency after integrating Chinese-made reduced bore ball valves into their systems, showcasing a trend where quality directly translates to performance.

Further analysis from the North American water treatment industry reflects similar outcomes. Several municipalities that switched to these improved valves reported decreased maintenance costs and longer service life across their infrastructure. The shift not only improved the overall functionality but also enhanced regulatory compliance—an essential aspect for industries operating under stringent safety standards. Such successful adoptions exemplify how Chinese innovations in valve technology are making significant inroads in competitive markets, proving that quality and performance can vastly influence global sales growth.

Future Prospects for China's Ball Valve Industry and Global Impact

China's ball valve industry is poised for significant growth, particularly in the reduced bore ball valve segment, which is gaining international recognition. With projections indicating the market for HPLC check valve pump ball valve seats will reach $21.27 million in 2024 and grow to $34.93 million by 2032, a robust growth rate of 6.39%, the dynamics of global sales are clearly shifting. This expansion underscores the increasing demand for high-quality, reliable valve solutions, driven by industrial applications and innovations coming from China.

As Chinese manufacturers continue to upgrade their product quality, they not only enhance competitiveness but also respond to the changing needs of global industries. The focus on technological advancements and consistency in performance creates a ripple effect across international markets, potentially redefining standards and expectations for ball valve functionality worldwide. This shift not only supports the domestic economy but also influences pricing and availability on a global scale, indicating a long-term transformation in supply chain dynamics within the valve manufacturing sector.