- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

7 Key Advantages of Choosing the Best Butterfly Valve for Your Applications

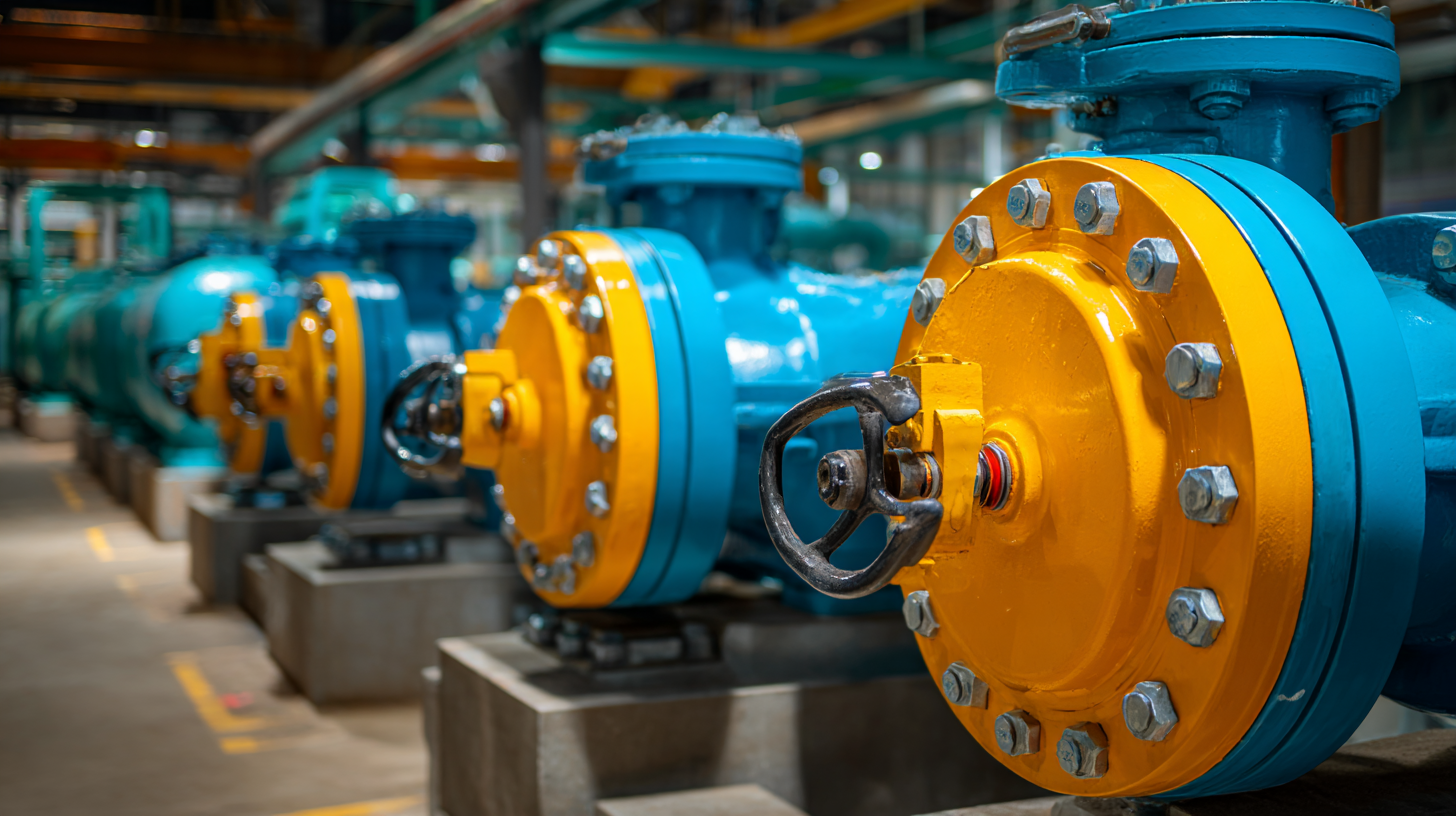

In the world of industrial applications, the selection of components plays a crucial role in the efficiency and longevity of operations. Among these components, the Butterfly Valve stands out for its unique advantages, particularly in terms of after-sales service and maintenance costs. According to a recent report by MarketsandMarkets, the global valve market is expected to reach $87.6 billion by 2025, with Butterfly Valves accounting for a significant share due to their cost-effective performance and reliability. The resilience and simplicity of design not only reduce the likelihood of failures but also lead to decreased maintenance efforts and associated costs, making them an essential choice for industries looking to optimize their systems. As companies increasingly prioritize operational uptime and budget efficiency, understanding the key benefits of selecting the right Butterfly Valve becomes imperative for achieving long-term success.

Understanding the Importance of Quality Butterfly Valves in Industry Applications

When selecting components for industrial applications, the importance of quality butterfly valves cannot be overstated. These valves play a critical role in controlling the flow of fluids, making their reliability essential for efficient operations. High-quality butterfly valves are designed to withstand extreme pressures and temperatures, ensuring their longevity and performance. Investing in top-grade valves minimizes the risk of leaks and failures, which can lead to costly downtime and potential safety hazards.

Moreover, quality butterfly valves are engineered for precision and ease of use. Their design allows for quick operation and minimal torque, which translates into lower energy consumption during operation. In industries where time and efficiency are paramount, the ability to swiftly regulate flow can have a significant impact on overall productivity. By understanding the importance of quality butterfly valves, companies can ensure they meet the stringent demands of their applications, thereby enhancing performance and sustainability in their operations.

Key Factors to Consider When Selecting a Butterfly Valve Manufacturer

When selecting a butterfly valve manufacturer, several key factors must be considered to ensure

optimal performance and reliability in your applications. One of the most critical aspects is the manufacturer’s experience in the industry.

According to a report by the International Valve Manufacturers Association, companies with over

20 years of experience in valve production have a significantly lower failure rate of

15%, compared to newer manufacturers, whose failure rates can reach upwards of 30%.

This experience translates to better quality control and expertise in producing valves that meet stringent industry standards.

Another essential factor is the material used in the valve construction. The choice of materials can significantly affect the valve's

durability and resistance to corrosion. Research indicates that valves made from

high-quality stainless steel can last up to 20% longer in harsh

environments compared to those made with inferior materials. It’s advisable to ensure that the manufacturer provides detailed specifications

regarding the materials used and offers warranties that reflect their confidence in their products.

Tips: Always request samples or case studies from manufacturers to assess their

product performance in real-world applications. Additionally, consider the manufacturer's certification and compliance with relevant industry

standards, as this can further guarantee the quality and reliability of their butterfly valves.

Evaluating Performance Metrics: What Makes a Butterfly Valve High-Quality?

When evaluating the performance metrics of butterfly valves, it is essential to consider a range of factors that dictate their quality and efficiency in applications. High-quality butterfly valves not only ensure reliable flow control but also optimize performance across various conditions. For instance, the design intricacies like the shape of the valve disc and the sealing mechanism play crucial roles in minimizing turbulence and pressure loss during operation, which can be vital in systems such as variable air volume (VAV) systems where airflow accuracy is paramount.

Moreover, the integration of advanced technologies such as artificial intelligence can further enhance the assessment of butterfly valve quality. By employing AI models, engineers can identify potential design errors in complex valve blueprints, ensuring that each component adheres to strict performance standards. This aligns with the latest trends in engineering where precision and reliability are prioritized, echoing findings from studies on various mechanical systems. Ultimately, selecting the best butterfly valve hinges on a thorough evaluation of these performance metrics, which can significantly impact system efficiency and longevity.

Benefits of Investing in Top-Tier Butterfly Valves for Long-Term Reliability

Investing in top-tier butterfly valves is essential for ensuring long-term reliability in various industrial applications. These valves are renowned for their ability to control flow with precision and efficiency, which is critical in today’s rapidly changing and complex market. By selecting high-quality butterfly valves, companies can significantly reduce maintenance costs and downtime, leading to enhanced operational efficiency. Furthermore, top-tier products often come with superior materials and design, providing greater resistance to wear and tear, thus extending their service life.

In an era where businesses face increasing volatility, the reliability of equipment cannot be overstated. The right butterfly valves can contribute not only to the integrity of fluid systems but also to the overall safety of operations. Companies looking to future-proof their processes must prioritize quality in their valve selection. Investing wisely in top-tier butterfly valves translates to robust performance and a strategic advantage in an unpredictable business landscape, ensuring that organizations can navigate challenges effectively.

Comparative Analysis: Premium versus Standard Butterfly Valves in Various Applications

When selecting a butterfly valve for your applications, it's essential to understand the differences between premium and standard options. Premium butterfly valves are engineered with higher-quality materials and advanced technology, which significantly enhances their performance and longevity. These valves often feature better sealing capacities, reduced operational torque, and superior resistance to corrosion, making them ideal for high-stakes environments such as the oil and gas industry or chemical processing plants.

Conversely, standard butterfly valves can be more economical, which makes them appealing for less demanding applications. While they may suffice for general water or air control in lower-pressure systems, they often fall short in terms of durability and efficiency when exposed to harsher conditions. The choice between premium and standard valves should consider the specific demands of the application, including pressure, temperature, and the nature of the media being controlled. Understanding these distinctions ensures you make a well-informed decision, leading to higher operational efficiency and cost savings in the long run.